|

At

the time my wife and I

decided to offer our sloop to the Maritime Museum, I

decided to make a

hull as a very high quality copy of the original just to

have the lines

available in case I decided to make

a complete model or use the copy for more models of the sloop. At

the time my wife and I

decided to offer our sloop to the Maritime Museum, I

decided to make a

hull as a very high quality copy of the original just to

have the lines

available in case I decided to make

a complete model or use the copy for more models of the sloop.

|

The hull replicas of my original

1880 model sloop - but without keels. The hull replicas of my original

1880 model sloop - but without keels.

Both

of these hulls to the left are a copies of the original

above but I wanted to see the shape of the boat without

a keel.

The paint on the model is semi gloss (now) and the look of the hull is

slightly different than the replicas and a different angle of view to

the immediate left. The paint finish makes a big difference. The

replica is within 1 mm in most places on the replica hull. For a short

time I had both side by side and they are very nearly the same.

And...the upper hull has a rail and the lower hull are to the deck

line (the blue line on the model.

The hull to the upper copy model is redwood finished with

yacht varnish and

a stub ready to take a bowsprit I will add the keel which I

find much easier

than trying to get the hull shape and the keel added at

the same time.

Some Trickery...both models to the left are nearly

identical!

The upper varnished model has "PhotoShoped keel". The

keel was borrowed

from the original above. Using Photoshop, I traced the shape of the keel

below, copied

it, and pasted it onto the varnished copy to the left

and blended both. Take a look at

the spotted damage of the keel below and then loot

above. You will see

most of the defects on the keel below in the keel above. And you will see a slight bend in the keel at the white waterline area of the above keel near the lower keel.

The was done to give you a better understanding of what

the copies on

this page will look as finished sloops. Presently my

plan is to use the

copy of a copy to make a fully rigged version of what I

know from the

sloop and by using information from some of the photos

of small 2

masted schooners. You can also see how much easier it is

to get a perfect hull shape, and then put the keel on.

The was done to give you a better understanding of what

the copies on

this page will look as finished sloops. Presently my

plan is to use the

copy of a copy to make a fully rigged version of what I

know from the

sloop and by using information from some of the photos

of small 2

masted schooners. You can also see how much easier it is

to get a perfect hull shape, and then put the keel on.

|

Doghole schooners and

commercial sloop lines.

|

WE

NEED DRAWINGS OF, AND DOCUMENTATION FOR, DOGHOLE

SCHOONERS

This is another place to

mention our need for documentation. We

desperately need drawings or sketches of doghole schooners.

All we have for a side view is the drawing I will make

from the sloop and a half model I will have access to.

If you have an

interesting hand made model or model parts or any kind or documentation

on dodhole schooners please let me know. If you prefer, I will look at

your photos and let you know what I think. If I have doubts, I now know

several experts who would be glad to look at the photos of the model,

or your documentation.

CONTACT ME BY EMAIL:

STEVE

( AT ) SLMH2006 (

dot ) NET

|

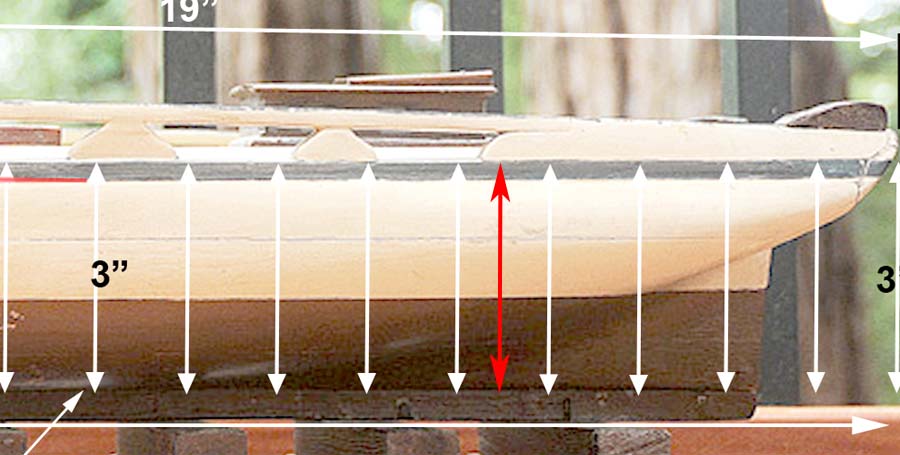

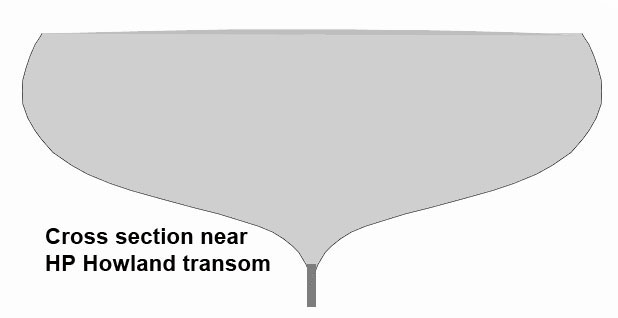

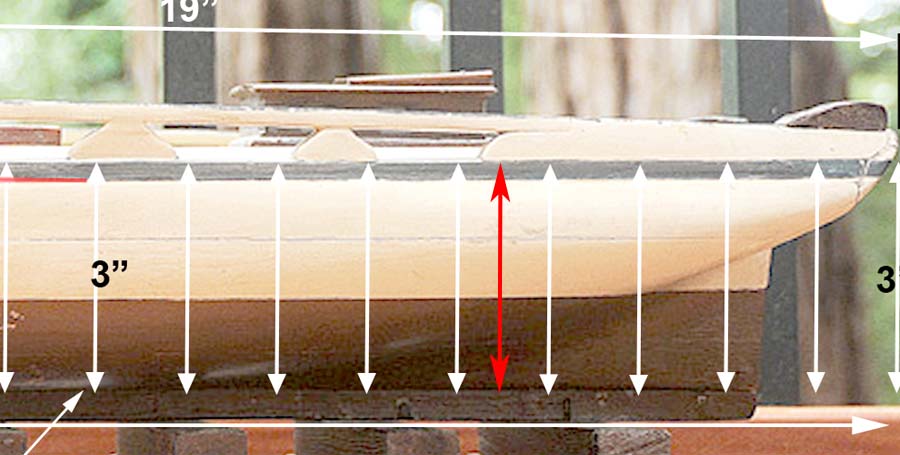

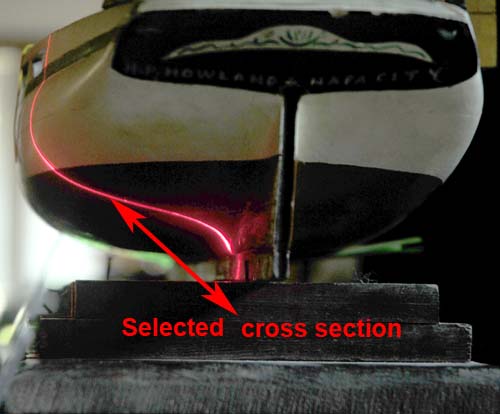

The side view of the model below shows a vertical red arrow. The

red

arrow represents the laser mark on the transom image below. Using

Photoshop it is possible to show only the red laser line on the

hull.

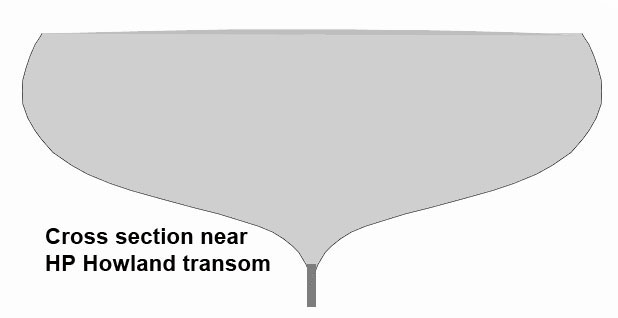

This idea was mentioned earlier This is just a quick statement to

emphasize the process. The red laser line can be converted to a

black

and white cross section. By showing a mirror image and combining

the

images you can PRINT on a stiff piece paper, a nice cross section

which

is the third image in this set. And by cutting the gray image in

half

and cutting the gray area out the piece of paper can be placed

against

the hull at the right point to measure and adjust the hull shape.

The profile below comes from hand applied laser lines to the sloop above.

Template

Note: the template is the light blue texturized area in this illustration.

Once I had enough profiles of the sloop model, I could make the full

sized model out of a soft wood. The light blue texturized area is a thick paper

template for the position measured on the sloop hull shape. I then adjusted each point of the hull according

to each different template.

For me this was half engineering and half sculpturing sanding carefully

and checking the template for each point on the hull on both sides. I

worked very slowly using finer and finer sand paper until the hull

looked and felt right. This porecess took me about a week to make a

precision copy of the original hull. An example is shown below.

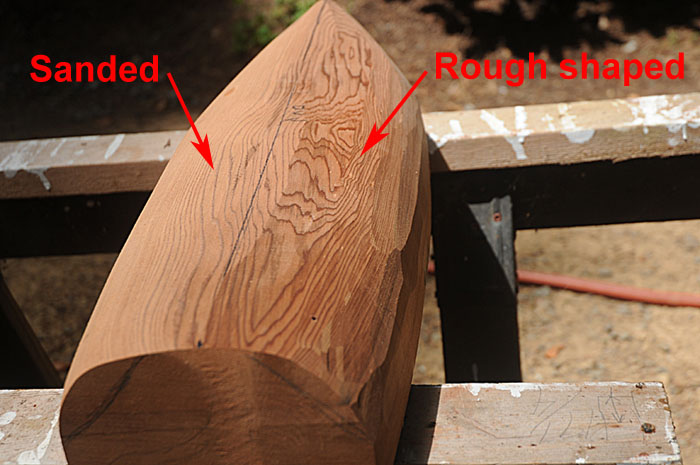

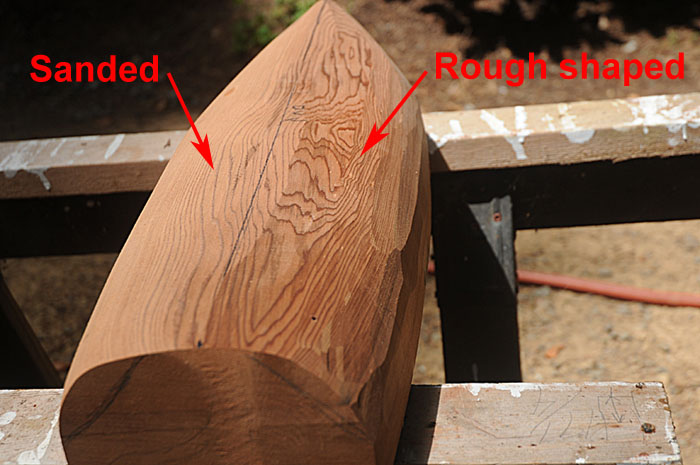

SOME EARLY WOODWORK

To

the left is an example of the start of hull work. The first stage is

done with whatever tools will work. I used a band saw, an electric

planer, a power sander, and a hand planer. To

the left is an example of the start of hull work. The first stage is

done with whatever tools will work. I used a band saw, an electric

planer, a power sander, and a hand planer.

Sanding down to the left side shape was done with #36 grit sandpaper on a power sander. Then #80 grit, etc.

By the way, #36 grit on a random-orbit rotary hand sander is like a planer...more wood can be lost than you think!

As time consuming as this looks a rough shape can be done in an hour. The main

trick is to stay over sized

to get to a point for the use of the precision template sanding and

final shaping. The wood in my examples is extremely dry redwood heart

wood in 2 inch slabs. This , by the way, is how the original model hull

was made - slabs of what I think was balsa. I don't know how much balsa

was available in The San Francisco area in 1880. But the model maker

may have been a captain in the Howland family. A captain would have a

chance to go to the South America and bring some balsa back to his home.

Cutting to much off the hull in this case is a serious mistake as always in woodworking. If you try this, take your time!

Start and finish

To

the left is a finished sloop hull without a keel on the model sloop.

The right side of the image, in a very rough state, is a start at a

doghole schooner. The schooner model will be about 30 inches,

representing a 75 foot schooner. To

the left is a finished sloop hull without a keel on the model sloop.

The right side of the image, in a very rough state, is a start at a

doghole schooner. The schooner model will be about 30 inches,

representing a 75 foot schooner.

Website

Under Construction Website

Under Construction

|

Website

Under Construction

Website

Under Construction

To

the left is an example of the start of hull work. The first stage is

done with whatever tools will work. I used a band saw, an electric

planer, a power sander, and a hand planer.

To

the left is an example of the start of hull work. The first stage is

done with whatever tools will work. I used a band saw, an electric

planer, a power sander, and a hand planer. To

the left is a finished sloop hull without a keel on the model sloop.

The right side of the image, in a very rough state, is a start at a

doghole schooner. The schooner model will be about 30 inches,

representing a 75 foot schooner.

To

the left is a finished sloop hull without a keel on the model sloop.

The right side of the image, in a very rough state, is a start at a

doghole schooner. The schooner model will be about 30 inches,

representing a 75 foot schooner. Website

Under Construction

Website

Under Construction